Alcomer® 1771

- Increases the yield of bentonite

- Increases penetration rates

- Helps reduce fluid loss

- Reduces overall drilling costs

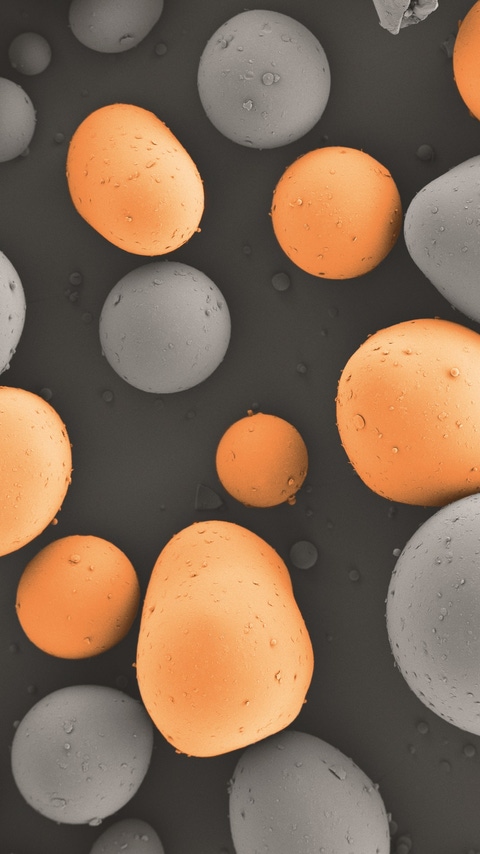

- Microbead form - dust-free, flows readily, disperses quickly

Oilfield Chemicals

As high-quality bentonite reserves become scarcer, it is common practice to add a small amount of polymer to the ore during milling, in order to guarantee that the bentonite will meet the API specification of minimum barrel yield without compromising fluid loss control.

Long-chained anionic polymers will increase mud viscosity by linking clay platelets together, thus these polymers are used as dry extenders to improve the yield of bentonite to API and OCMA specification; or as wet-extenders for use in low-solids, freshwater non-dispersed mud systems. Wet extension is particularly useful when spudding a well or prior to logging operations when extra carrying capacity is required.

Alcomer® 1771 brings additional benefits due to its superior bead form, which gives easy mixing, less dust, good solubility and reliable efficient performance.

This product is a low-medium molecular weight, fully anionic polyacrylate produced in BASF’s unique microbead form. It is used primarily in low-solids, non-dispersed fluids to extend the yield of bentonite.

Alcomer® 180 provides bentonite extension and can be more efficient on some clays, but should not be used on low grade ores and is in powder form.