The Application of LixTRA™ offers the following benefits:

- Improved Ore Wetting

- Higher Metal Recovery

- Faster Metal Recovery

- Reduced Net Acid Consumption

- Lower Mining Costs

- Extends Life of Mine

- Potential to Enhance Sulfide Leaching

Mining Solutions

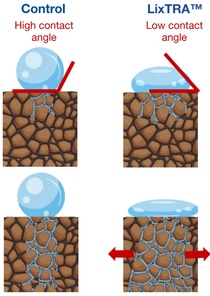

Leaching is typically the first stage of a hydrometallurgical process and is followed by solution concentration/purification and recovery to produce a high purity metal or compound. There are several different leach methods, with the choice dictated by the grade of ore, with lower grades employing relatively unsophisticated processes such as a dump leach and higher grades tolerating more costly processes such as an agitated leach. However, the efficiency of all leaching processes is dependent on high lixiviant ore contact to facilitate the dissolution of the desired metal into an aqueous phase.

The industry is continually faced with depleting ore grades and in need of new sustainable extraction techniques to meet the ever increasing demand for metals such as copper. BASF has therefore developed LixTRA™, a novel leaching reagent designed to increase lixiviant wetting of the ore, which results in faster and higher metal recovery.

LixTRA™ is a surfactant that boosts copper heap and dump leach performance by increasing metal recovery and reducing mining costs in an environmentally sound and sustainable manner.

It is a liquid, which is added in small (ppm) quantities to the irrigation system of the leaching process. It is a non-hazardous, low foaming, non-ionic oligomer.

Due to its novel chemical structure, LixTRA™ has lower surface activity compared to most surfactants and is far less active than leaching aids that have been previously investigated.

LixTRA™ is fully compatible with downstream solvent extraction/electrowinning processes and does not negatively affect microbial activity.